Demonstrations of digital work instructions at Flanders Make symposium

Demonstrations of digital work instructions at Flanders Make symposium

We would like to highlight the demos 'Converter for digital work instructions' and 'Adaptive ergonomics work instructions'. You could also discover these demos during our annual Symposium in the Brabanthal in Leuven on 25 October.

Creating digital workinstructions (DWI’s)

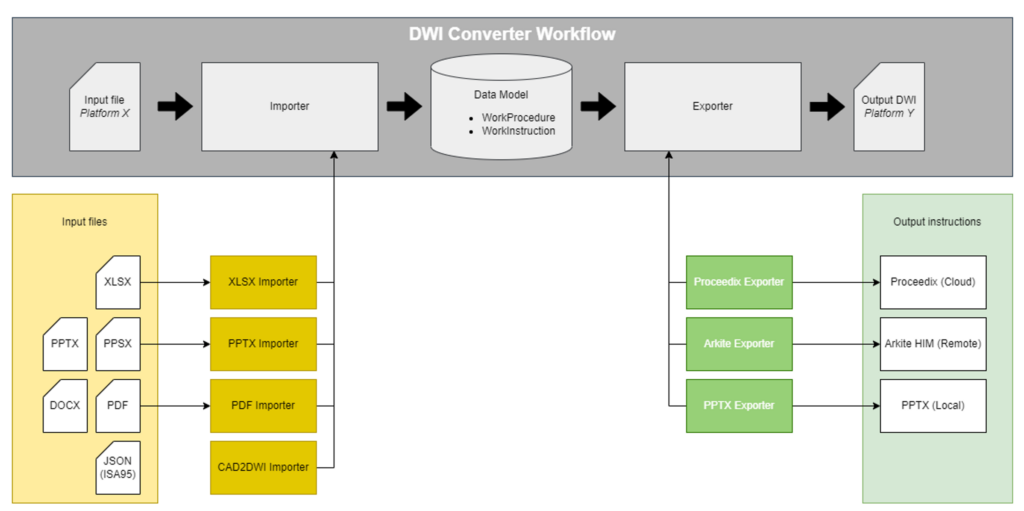

Creating digital work instructions is a time-consuming task, making their widespread implementation within an enterprise difficult. In addition, instructions are programmed in a platform-specific format and are therefore highly dependent on the chosen platform. Nevertheless, most companies have a large source of information in the form of existing procedures, instructions or checklists. Moreover, these are usually also sufficiently structured to convert them to digital work instructions in an automatic way. To make this possible, we have developed a generic work instruction model that can immediately convert collected data (e.g. PowerPoint, Word or Excel) to an existing commercial platform.

By automatically parsing semi-structured document types into a uniform format (ISA95), we reduce start-up costs and enable communication between different DWIs on different platforms. This way, we can create DWIs up to 90% faster.

During the demo, you can see how to:

- Choose different input documents for the same assembly procedure such as Excel, PowerPoint, photos, videos, etc.

- Choose an output format to display instructions such as Proceedix, Arkite, Azumuta etc.

Then the conversion will start and highlight the way information has been recorded from different sources in the standardised ISA-95 format.

Adaptive ergonomic workinstructions

Heavy and repetitive tasks can lead to injuries or harm to operators. A correct ergonomic way of working can prevent this. Therefore, we need operator support technology that provides instructions to work in an ergonomic way.

During the demo, you can find newly developed digital work instructions that monitor operators' posture in real-time and provide them with correct ergonomic information. In addition, the system is also able to adapt to the content of the work instructions to detect potential risks. While using this DWI in a manual assembly process, operators will generally experience a reduction in the calculated REBA (Rapid Entire Body Assessment) score.