Smarter use of digital work instructions through state-tracking

Smarter use of digital work instructions through state-tracking

Digital work instructions can provide new operators with targeted guidance on assembly tasks. It also benefits more experienced operators who assemble many variations of products in small runs. Augmented Reality, using a headset such as e.g. the Microsoft HoloLens 2, guides the operator step by step during the execution of an assembly task without having to stop work to consult the work instructions. However, going through these steps manually (by pressing a button to go to the next instruction), can still cause errors if a wrong part is used, or a certain operation is skipped.

State tracker

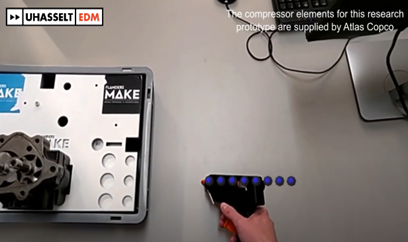

Flanders Make@UHasselt's State Tracker is a solution that avoids the above mistakes. Via the visual camera sandaard present in AR headsets, it immediately detects whether an object is placed correctly. Actions such as tightening screws, or following a certain path during the assembly task (e.g. when gluing) can also be monitored this way. Thanks to this detection, a next instruction can automatically be given when a previous action was performed correctly and an operator can be guided even more specifically. In addition, an incorrect action can also be detected.

The formatting of the work instructions used in this state tracker can be done directly from a CAD model. The Flanders Make tool for semi-automatic drafting of digital work instructions, CAD2DWI, takes into account the various steps to be detected by the State Tracker in addition to drafting the work instructions. This enables the use of the State Tracker without additional adjustments to the working environment or digital work instructions.