Image processing via AI at high speed for 3D metal printing

Image processing via AI at high speed for 3D metal printing

3D printing of objects allows complex designs to be developed on a computer and then produced without much consideration of the limitations of traditional production methods. It also allows us to quickly produce prototypes, print objects where only one piece is needed (e.g. customised medical implants), or produce complex structures that are impossible via conventional production methods. Examples include massive structures with complex internal channels (e.g. engine block or elements with built-in cooling or ventilation), optimised parts (e.g. lightweight but strong aerospace parts with complex shape), or complex 3D shapes that are difficult to produce (e.g. turbine blades, pump impellers, mesh-shaped structures, etc.).

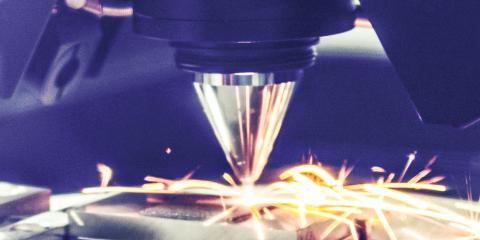

3D printing of metal objects is possible through several techniques. A popular method is powder bed fusion via selective melting with a laser where an object is built up layer by layer:

- A thin layer of metal powder is deposited on the building platform or object under construction

- The relevant layer is melted via laser, and the object raises by 1 layer

- The build platform drops 1 layer, new powder is deposited and the process repeats itself

This type of metal 3D printing can be done in different alloys (stainless steel, titanium, Cobalt-Chrome alloys, ...), with diverse applications in aerospace, machine production, or the medical industry. However, due to the high quality requirements, thorough quality control of the produced objects is necessary. An alternative is to monitor the melting process itself during production, thus intercepting any errors or problems already during production and possibly correcting or adjusting them.

Control system developed at Flanders Make

A possible control system developed at Flanders Make is based on monitoring the melting process with a high-speed camera, which collects images at 20 000 frames per second. These images are then processed via deep learning to arrive at a prediction of quality parameters.

The video alongside demonstrates this procedure for predicting system parameters using on-axis video images.