Innovations for visual inspection

Implement Vision AI in your production process

Do you want to increase the speed and accuracy of your quality control processes? With today's advances in technology, it's not only possible - it's within your reach.

The role of visual inspection in manufacturing

Visual inspection plays a pivotal role in the manufacturing industry, performing critical functions such as locating parts, detecting defects such as scratches, and coordinating the positioning of objects for robotic handling. With recent technological innovations, especially when combined with artificial intelligence (AI), it's now possible to achieve fast and robust results, often exceeding accuracy and speed of manual processes performed by humans.

At Flanders Make, we're pioneering projects that use these innovations to provide practical solutions for businesses. Our initiatives aim to demonstrate how the integration of AI with visual inspection can dramatically improve operational efficiency.

Hands, eyes and brain working together

Imagine a system where robotics ('the hands'), AI ('the brain') and vision technology ('the eyes') are seamlessly integrated. Innovations in this area are improving the way these components interact, particularly in quality control. Humans typically use their eyes and hands in tandem for inspection tasks, adjusting object orientation and lighting for optimal visibility. Our brains guide these actions efficiently, learning to quickly identify defects and the best conditions for inspection. By using 'active vision' - using movement to adjust the viewpoint - and AI, we can replicate and enhance this natural process in a machine context.

There are already many technologies that can mimic human capabilities. In robotics, we are creating 'the hands', artificial intelligence can be thought of as 'the brain' and vision technology as 'the eyes'. Important new innovations are happening in the area of making these three work better together.

Take the case of defect detection: humans use our eyes in combination with our hands - they can bring an object closer and rotate it so that we can inspect it from different perspectives and in different light. Our brains make sure we do this efficiently: we learn to spot defects and their patterns quickly, and to remember which angles and lighting conditions give the clearest results. How can we replicate this with existing technologies? The key is to combine 'active vision' (= using movement) with AI.

Active Vision: Automatically Optimizing Inspection Viewpoints

Active vision leverages motion to capture images from multiple viewpoints, enabling flexible and comprehensive defect detection across all surfaces. This dynamic approach is particularly effective for automating inspection processes, especially in complex parts or low-volume production.

We’ve developed an advanced robotic setup, equipped with multiple lighting options, allowing for flexible inspection of parts from various angles. This setup offers several advantages: surfaces can be imaged under different lighting conditions and from multiple viewpoints, with the fused data leading to more stable and reliable AI-driven defect detection.

One of the challenges in active vision is determining the optimal sensor placement to ensure that every surface of an object is imaged. Our approach addresses this by using CAD data to automatically calculate sensor positions, maximizing coverage and thus inspection accuracy. These sensor positions are integrated with an automatic path planning algorithm to enable comprehensive inspection by a robot.

Beyond standard image-based inspection, we are also developing automated routines for 3D scanning tasks. These routines further enhance the speed, accuracy, and non-contact nature of quality control processes.

Are you interested in fast, non-contact quality control? We invite you to join our dissemination project, ACCUMONIT: Efficient Accuracy Prediction and Monitoring for Machining.

Camera? Action!

This photo showcases one of our flexible inspection setups, designed for testing and optimizing the ideal light and camera configurations. The camera, mounted on a robot arm, works with multiple light sources, including a ring light, side directional lighting, and an overhead light (not visible in the image), creating a wide range of lighting conditions. The turntable further enhances flexibility, allowing for easy adjustments.

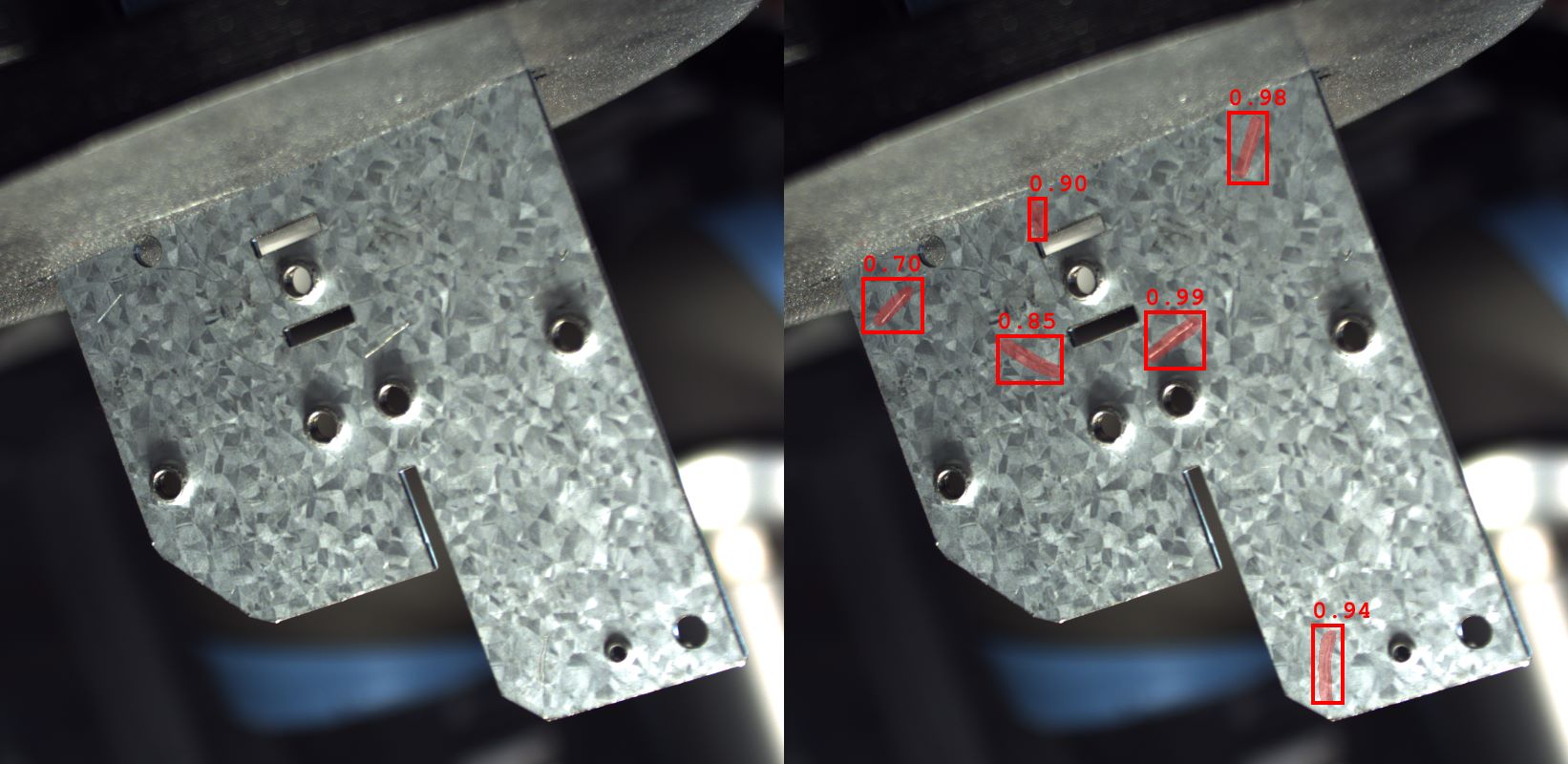

A picture of a metal test piece illuminated under different lighting conditions. The two images clearly demonstrate how varying light sources and angles reveal different scratches. Although it is the same plate, certain defects become visible in one image that are not apparent in the other, underscoring the importance of adjusting lighting angles to detect surface flaws.

AI-Based Quality Inspection: Streamlining Data Collection and Enhancing Robustness

Our AI-based quality inspection system is designed to make defect detection more accurate and efficient. By automating the image capture process, our robotic setup can generate a large number of images from a single object, capturing it from multiple angles and under different lighting conditions. This variety introduces natural variations in the dataset, which is crucial for training robust AI models.

To streamline the training process, we’ve developed a semi-automatic annotation tool that leverages the 3D information: position of the object and position from which the image is taken. With this tool, each defect only needs to be annotated once; if the same defect appears in another image, the system automatically applies the annotation, significantly reducing the manual effort required. If you are interested in this topic also checkout this blogpost: We developed a double proof of concept where we used two innovative methods to train a complete and robust AI model in just one day.

In addition to the automated image capture, we employ data augmentation techniques during training to increase variability in the dataset, further enhancing the AI model’s robustness. With a small number of objects—usually 10 to 20—our AI model generalizes well to new objects. Techniques like background removal and completely shielding the system against lighting conditions can reduce variability further, but our AI has proven capable of handling variations effectively without these.

The active vision system’s ability to image defects under different lighting conditions ensures that all defects are captured at least once. We’ve also developed algorithms that fuse AI results from multiple views, providing a comprehensive and robust detection process that minimizes the risk of missing any defects.

Want a demonstration of innovative methods for data annotation and training? Our dissemination project ‘Easy AI for Industry’ aims to make smart computer vision accessible for production environments, even for companies that do not have a large R&D department. Besides demonstrations and knowledge transfer, we are also working on an easily deployable software toolbox for defect detection, object recognition, object counting and position estimation.

Just the beginning?

Vision technologies are fundamentally changing the manufacturing landscape and offer limitless potential to improve the way industries operate. Not only are these technologies revolutionising quality control through reliable visual inspection, they are also streamlining the entire production process.

Instant defect detection: Advanced vision technologies detect defects instantly, even during the fastest production processes. This rapid identification enables immediate corrections, reducing waste and increasing line efficiency.

Subtle defect detection: Vision AI can detect even the most subtle defects - those with low contrast that would typically escape the human eye. This capability ensures a higher standard of product quality and consistency, as every item that passes through the production line is thoroughly and accurately inspected.

Increased quality, speed and flexibility: Companies can adapt more quickly to new products or changes in product design, with less downtime and lower costs. The ability to respond quickly to market demands without compromising quality is a critical factor for any manufacturing operation.

One of the most significant benefits of these innovations is the ability to implement them with minimal manual programming and labelling. New innovations will continue to improve vision technology and set new standards in manufacturing excellence. To be continued!